EGS Reservoirs: Unleashing Power with Hydraulic Fracturing!

Introduction to Enhanced Geothermal Systems (EGS) and Reservoir Creation

Enhanced Geothermal Systems (EGS) represent a promising frontier in renewable energy, offering the potential to harness the Earth's abundant thermal energy even in locations lacking naturally occurring hydrothermal resources. Unlike conventional geothermal systems that rely on readily accessible hot water or steam, EGS Technology involves creating artificial reservoirs by stimulating existing, hot, but impermeable rocks deep beneath the Earth's surface. The core challenge in developing a successful EGS lies in enhancing the Permeability Enhancement of these rocks, allowing water to circulate through the fractured network, extract heat, and return to the surface for power generation. This process fundamentally requires understanding Reservoir Engineering principles and employing effective Stimulation Techniques. The primary goal is to establish a sustainable and economically viable geothermal resource, and achieving this relies heavily on the application of Hydraulic Fracturing methods. Without sufficient permeability, fluid flow is limited, and the efficiency of heat extraction is drastically reduced, rendering the EGS project economically unfeasible. Therefore, a deep understanding of Fracture Mechanics is crucial for successful implementation of EGS technology.

The Role of Hydraulic Stimulation in EGS

Hydraulic Fracturing, often referred to as hydrofracking, is a critical technique for Permeability Enhancement in EGS. The process involves injecting high-pressure fluid into the targeted rock formation to induce fractures, effectively creating pathways for fluid flow where none previously existed, or enhancing existing fracture networks. The injected fluid typically consists of water, proppants (such as sand or ceramic beads), and chemical additives. The high pressure overcomes the rock's tensile strength, causing it to fracture. The proppants then serve to keep these fractures open after the pressure is released, ensuring sustained Permeability Enhancement. The location, orientation, and interconnectedness of these fractures are crucial for determining the overall effectiveness of the EGS reservoir. Careful monitoring and modeling are essential to control the fracture propagation and avoid undesired consequences, such as induced seismicity. The success of Hydraulic Fracturing in EGS depends on several factors including the rock type, in-situ stress conditions, and the properties of the injected fluid. Optimizing these parameters is vital for maximizing the Geothermal Energy extracted and minimizing environmental impact.

Microseismic Monitoring

Microseismic monitoring is a crucial tool employed during Hydraulic Fracturing operations in EGS projects. It involves deploying a network of sensitive seismometers, both on the surface and in boreholes, to detect the tiny seismic events (microseisms) caused by the fracturing process. These microseisms provide valuable information about the location, size, and orientation of the induced fractures. By analyzing the microseismic data in real-time, engineers can track the progress of the fracture network development and adjust the injection parameters accordingly. This allows for a more controlled and efficient Permeability Enhancement process, minimizing the risk of inducing larger, potentially damaging earthquakes. Furthermore, microseismic monitoring helps to optimize the placement of subsequent injection wells, ensuring that they are strategically positioned to maximize the connectivity of the created fracture network. The data also provides insights into the stress field within the rock mass, which is essential for predicting future fracture behavior and long-term reservoir performance. Therefore, microseismic monitoring is an indispensable component of EGS development.

Fluid Chemistry and Proppant Selection

The selection of the appropriate fluid chemistry and proppant type is critical for the long-term success of Hydraulic Fracturing in EGS. The injected fluid must be compatible with the reservoir rock and avoid causing chemical reactions that could lead to scale formation or fracture closure. Various chemical additives can be used to control fluid viscosity, reduce friction, and prevent corrosion. The proppant material must be strong enough to withstand the high pressures within the fractures and resist crushing or degradation over time. The size and shape of the proppant particles also influence the fracture conductivity. Careful consideration must be given to the temperature and chemical environment of the reservoir when selecting both the fluid chemistry and the proppant type. Laboratory testing is often performed to evaluate the compatibility of different fluids and proppants with the reservoir rock under simulated conditions. The goal is to maximize the long-term Permeability Enhancement of the fractured network and ensure the sustained performance of the EGS reservoir. This aspect ties deeply with Reservoir Engineering.

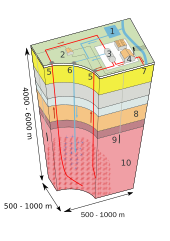

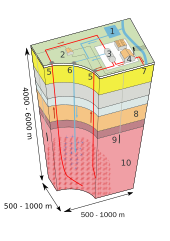

EGS Reservoir Creation Process: A Step-by-Step Overview

The creation of an EGS reservoir is a complex and multi-stage process involving detailed geological and geophysical characterization, well drilling, Hydraulic Fracturing, and long-term monitoring. Initially, a potential site is evaluated based on its geothermal gradient, geological setting, and the presence of suitable rock formations at depth. Geophysical surveys, such as seismic reflection and gravity measurements, are conducted to image the subsurface and identify potential target zones for EGS development. Next, exploratory wells are drilled to obtain core samples and conduct downhole logging to characterize the rock properties, temperature, and stress conditions. Based on this information, a stimulation strategy is designed to optimize the fracture network development. The Hydraulic Fracturing process is then carried out, typically in multiple stages, by injecting high-pressure fluid into the wellbore. Microseismic monitoring is used to track the fracture propagation in real-time. After the stimulation is completed, circulation tests are performed to assess the Permeability Enhancement and evaluate the reservoir's performance. The final step involves the construction of production and injection wells, connected by the stimulated fracture network, to extract heat from the reservoir. Continuous monitoring is essential to ensure the long-term sustainability of the EGS operation and prevent induced seismicity. The whole process is inherently reliant on solid Reservoir Engineering knowledge.

Techniques for Enhancing Permeability

Beyond traditional Hydraulic Fracturing, several other Stimulation Techniques are being explored to further enhance Permeability Enhancement in EGS. These include chemical stimulation, thermal stimulation, and explosive stimulation. Chemical stimulation involves injecting reactive fluids into the fractures to dissolve minerals and increase the fracture aperture. Thermal stimulation utilizes the injection of cold water to induce thermal stress and promote fracture propagation. Explosive stimulation involves detonating small charges within the wellbore to create new fractures or enhance existing ones. Each of these techniques has its own advantages and disadvantages, and the choice of the most appropriate technique depends on the specific geological conditions and reservoir characteristics. Hybrid approaches, combining multiple Stimulation Techniques, are also being investigated to achieve optimal Permeability Enhancement. The goal is to create a highly interconnected and conductive fracture network that allows for efficient heat extraction and long-term reservoir sustainability. Thorough understanding of Fracture Mechanics is indispensable for the successful implementation of these techniques.

Shear Stimulation

Shear stimulation is a specific type of Hydraulic Fracturing designed to induce shear slip along pre-existing fractures and faults within the rock mass. Unlike conventional hydrofracking that aims to create new tensile fractures, shear stimulation focuses on reactivating existing weaknesses in the rock. This is achieved by carefully controlling the injection pressure and fluid volume to induce small, controlled shear displacements. The resulting shear slip enhances the Permeability Enhancement of the fracture network by creating dilation and reducing the frictional resistance to fluid flow. Shear stimulation is particularly effective in crystalline rocks with well-developed fracture systems. It also has the potential to reduce the risk of inducing larger earthquakes, as it avoids the creation of large, new fractures. Precise monitoring of microseismic activity is essential to ensure that the shear stimulation process is controlled and localized. Shear stimulation is an increasingly important technique for EGS development, offering a more targeted and potentially less disruptive approach to Permeability Enhancement.

Acidizing

Acidizing is another Stimulation Technique used to enhance Permeability Enhancement in EGS reservoirs, particularly in carbonate or sandstone formations. This technique involves injecting acid solutions into the wellbore and fractures to dissolve minerals and increase the fracture aperture and conductivity. Hydrochloric acid (HCl) is commonly used to dissolve carbonate minerals, while hydrofluoric acid (HF) is used to dissolve silicate minerals in sandstone. The acid reacts with the rock matrix, creating new pathways for fluid flow and removing any existing blockages or scale deposits within the fractures. The effectiveness of acidizing depends on the type of acid used, the concentration of the acid, the temperature and pressure of the reservoir, and the mineral composition of the rock. Careful consideration must be given to the potential for corrosion of the wellbore and surface equipment during acidizing operations. Furthermore, it's important to manage the spent acid solution properly to minimize environmental impact. Acidizing can be used as a standalone Stimulation Technique or in combination with Hydraulic Fracturing to further enhance the Permeability Enhancement of the EGS reservoir.

Challenges and Future Directions

While Hydraulic Fracturing has proven to be an effective technique for Permeability Enhancement in EGS, it also presents several challenges. One of the primary concerns is the potential for induced seismicity, which can be mitigated through careful monitoring and control of injection parameters. Another challenge is the long-term sustainability of the stimulated reservoir, as fracture closure and mineral precipitation can reduce permeability over time. Addressing these challenges requires a multidisciplinary approach, integrating advanced modeling, monitoring, and optimization techniques. Future research will focus on developing more sophisticated Stimulation Techniques, improving our understanding of fracture mechanics, and enhancing our ability to predict and control reservoir behavior. The application of machine learning and artificial intelligence is also expected to play a significant role in optimizing EGS operations. Ultimately, the goal is to develop sustainable and economically viable EGS Technology that can contribute significantly to the global energy transition. This relies on the continuous improvement of our EGS Technology. The use of alternative fracturing fluids, such as supercritical CO2, is also being explored to reduce water consumption and minimize environmental impact. There is a strong interplay between Geothermal Energy, Hydraulic Fracturing, and environmentally-conscious practices.

Evaluating Stimulation Techniques

Selecting the right Stimulation Techniques for an EGS project requires careful evaluation. The geological characteristics of the area need to be thoroughly understood before any Permeability Enhancement can take place. Consider the factors in the table below.

| Factor | Description | Importance |

|---|---|---|

| Rock Type | Granite, sandstone, carbonate, etc. Different rock types respond differently to hydraulic stimulation. | Critical |

| Stress Field | In-situ stress conditions influence fracture orientation and propagation. | Critical |

| Temperature | Reservoir temperature affects fluid properties and chemical reactions. | High |

| Fracture Density | The presence of pre-existing fractures influences the effectiveness of stimulation. | High |

| Fluid Compatibility | The compatibility of the stimulation fluid with the reservoir rock is crucial. | Critical |

| Cost | The economic viability of the stimulation technique is an important consideration. | Medium |

| Environmental Impact | Minimize the environmental impact of the stimulation process. | Critical |

Performance Analysis After Stimulation

After performing Hydraulic Fracturing it is important to gauge the effectiveness of the Permeability Enhancement. Monitoring fluid flow rates, pressure drops, and temperature changes provide invaluable information. The table below lists the key performance indicators.

| Metric | Description | Units | Ideal Range |

|---|---|---|---|

| Flow Rate | Volume of fluid extracted per unit time. | m3/s or gallons/min | Varies depending on reservoir size |

| Pressure Drop | Difference in pressure between injection and production wells. | MPa or psi | Optimized to maximize flow while minimizing pump energy |

| Temperature | Temperature of the extracted fluid. | °C or °F | High as possible for efficient power generation |

| Tracer Tests | Used to understand the connectivity between wells. | Concentration vs. Time | Fast breakthrough indicates good connection |

| Microseismic Activity | Continued monitoring to evaluate fracture stability. | Magnitude | Keep below acceptable levels |

FAQ

Here are some frequently asked questions about creating EGS reservoirs using Hydraulic Fracturing:

- What is the main goal of hydraulic stimulation in EGS?

- The primary goal is to enhance the Permeability Enhancement of the rock formation, allowing water to circulate and extract heat efficiently. This ultimately enables the production of Geothermal Energy from otherwise impermeable rocks.

- What are the potential risks associated with Hydraulic Fracturing?

- The main risks include induced seismicity, groundwater contamination, and surface disturbances. However, these risks can be mitigated through careful site selection, monitoring, and regulatory oversight.

- How is the success of Hydraulic Fracturing assessed?

- The success is assessed by monitoring fluid flow rates, pressure drops, temperature changes, and microseismic activity. Tracer tests can also be used to evaluate the connectivity between injection and production wells.

- Is Hydraulic Fracturing environmentally friendly?

- While Hydraulic Fracturing can have environmental impacts, these can be minimized through best practices. The use of closed-loop systems, water recycling, and alternative fracturing fluids can reduce water consumption and minimize the risk of contamination. EGS Technology offers a clean energy source.