EGS Breakthrough: Geomechanics Secrets to Enhanced Fracturing!

Geomechanics for EGS Success: Understanding In-Situ Stress, Brittleness, and Fracture Initiation

Developing successful Enhanced Geothermal Systems (EGS) requires a thorough understanding of subsurface geomechanical conditions. These conditions critically influence the efficiency of creating and maintaining permeable fracture networks essential for heat extraction. Three key parameters—in-situ stress, rock brittleness index, and fracture mechanics pertaining to fracture initiation—play a pivotal role in EGS design and operation. A comprehensive assessment of these factors is crucial for optimizing EGS reservoir stimulation and ensuring the long-term viability of geothermal energy production.

The Significance of In-Situ Stress in EGS Development

The in-situ stress state within the subsurface is the natural stress field existing before any engineering intervention. It’s a primary driver controlling fracture orientation, fracture aperture, and the effectiveness of hydraulic stimulation. Understanding the magnitude and orientation of the three principal stresses (maximum horizontal stress, minimum horizontal stress, and vertical stress) is paramount for predicting fracture propagation and controlling the overall geometry of the stimulated reservoir volume (SRV). A well-defined stress profile is essential for designing efficient hydraulic fracturing strategies and maximizing the contact area between the engineered fractures and the hot, dry rock. Misunderstanding the stress regime can lead to inefficient fracturing, non-optimal reservoir connectivity, and ultimately, reduced geothermal energy production.

Determining In-Situ Stress Orientation and Magnitude

Accurate in-situ stress measurement is essential. This typically involves a combination of techniques including borehole breakouts analysis from wellbore image logs, extended leak-off tests (XLOTs), minifrac tests, and differential strain curve analysis (DSCA) on core samples. Each method provides different pieces of information, and integrating them provides a more complete picture of the in-situ stress field. The accuracy of these measurements directly impacts the success of the EGS reservoir stimulation.

Impact of Stress Anisotropy

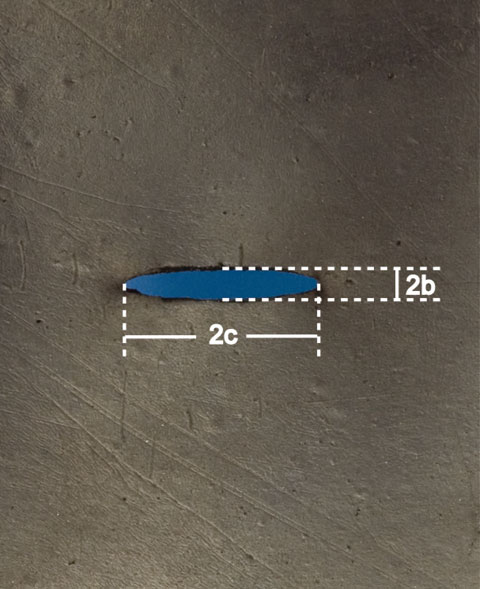

The difference between the maximum and minimum horizontal stresses (stress anisotropy) significantly affects fracture geometry. High stress anisotropy tends to result in long, narrow fractures aligned with the maximum horizontal stress, while lower anisotropy can lead to more complex fracture networks. Understanding the degree of stress anisotropy is therefore critical for predicting the shape and extent of the stimulated reservoir.

The orientation of existing natural fractures relative to the in-situ stress field also dictates their likelihood of reactivation during stimulation. Fractures oriented favorably with respect to the stress field are more easily opened and propagated, creating pathways for fluid flow.

Rock Brittleness and Its Influence on Fracture Propagation

Rock brittleness index is a measure of a rock's tendency to fracture under stress rather than deform plastically. In EGS applications, high brittleness is generally desirable because it promotes the creation of complex, interconnected fracture networks during hydraulic fracturing. Brittle rocks tend to fracture more easily and with greater fracture density compared to ductile rocks, leading to a more extensive SRV. Evaluating rock brittleness index is therefore crucial in assessing the suitability of a potential EGS site and optimizing stimulation parameters.

Several methods are used to determine rock brittleness index, including laboratory testing of core samples (e.g., triaxial compression tests, Brazilian tensile strength tests), and empirical correlations based on mineral composition and sonic logs. Each method provides a different perspective on brittleness, and integrating these results provides a more robust assessment. The calculated rock brittleness index informs decisions regarding stimulation fluid selection, injection rates, and overall stimulation strategy to effectively create a sustainable EGS reservoir stimulation.

The Relationship Between Mineral Composition and Brittleness

The mineral composition of a rock significantly influences its brittleness. Rocks rich in quartz and feldspar tend to be more brittle than rocks rich in clay minerals or ductile minerals like mica. Quantitative mineralogy, derived from X-ray diffraction (XRD) or QEMSCAN analysis, can be used to predict the bulk brittleness of a rock formation.

A high quartz content, for example, correlates positively with brittleness, while a high clay content often indicates lower brittleness and a greater tendency for plastic deformation. These mineralogical factors are important when determining the optimal fracturing strategies.

Fracture Initiation and Propagation: A Fracture Mechanics Perspective

Understanding the principles of fracture mechanics is essential for predicting how fractures will initiate and propagate during hydraulic fracturing in an EGS reservoir stimulation. The fracture initiation pressure, which is the pressure required to create a new fracture or reopen an existing one, depends on the in-situ stress state, the tensile strength of the rock, and the presence of pre-existing flaws or fractures. Once a fracture initiates, its propagation is governed by the stress intensity factor at the crack tip and the fracture toughness of the rock. A higher stress intensity factor and a lower fracture toughness promote fracture propagation.

The orientation of the borehole relative to the in-situ stress field also influences fracture initiation. Fractures tend to initiate along the borehole wall in the direction of the maximum horizontal stress. Understanding these relationships allows for strategic placement and orientation of injection wells to optimize fracture development.

The type of stimulation fluid used can also affect fracture initiation and propagation. Fluids with high viscosity and high injection rates can generate higher pressures at the borehole wall, promoting fracture initiation. The chemical composition of the fluid can also interact with the rock matrix, potentially altering its mechanical properties and affecting fracture propagation. Therefore, proper consideration must be given when determining hydraulic fracturing strategies in relation to the fracture mechanics of the rock and subsurface.

Integrating Geomechanics into Reservoir Simulation

Geomechanical considerations must be integrated into reservoir simulation models to accurately predict the performance of Enhanced Geothermal Systems. Traditional reservoir models often assume that the rock matrix is rigid and that permeability is constant. However, in reality, the rock matrix deforms under changing stress conditions, and permeability is highly sensitive to fracture aperture, which is controlled by the effective stress acting on the fractures. Geomechanical-reservoir coupling allows for a more realistic representation of the complex interactions between fluid flow, heat transfer, and rock deformation in EGS reservoirs. This results in more accurate predictions of reservoir performance and optimized operating strategies.

By incorporating geomechanical data into reservoir simulation, engineers can better predict the evolution of the stimulated reservoir volume, the changes in permeability and porosity over time, and the long-term sustainability of geothermal energy production. This integrated approach is essential for minimizing operational risks and maximizing the economic viability of Enhanced Geothermal Systems.

Best Practices for Geomechanical Site Characterization

A robust geomechanical site characterization program is essential for the success of any EGS project. This program should include the following components:

- Comprehensive in-situ stress measurement campaign utilizing multiple techniques.

- Detailed analysis of core samples to determine rock brittleness index, fracture toughness, and other relevant mechanical properties.

- Characterization of natural fractures, including their orientation, spacing, and aperture.

- Integration of geomechanical data into reservoir simulation models to predict reservoir performance.

- Continuous monitoring of reservoir pressure and deformation during stimulation and production to validate model predictions.

By following these best practices, EGS developers can minimize the risks associated with subsurface uncertainties and optimize the design and operation of their geothermal systems. Effective site characterization is the cornerstone of successful EGS reservoir stimulation and long-term geothermal energy production.

| Parameter | Measurement Technique | Impact on EGS Performance |

|---|---|---|

| In-situ stress Magnitude and Orientation | Borehole breakouts, XLOTs, Minifrac Tests, DSCA | Controls fracture orientation, aperture, and SRV geometry. Influences stimulation strategy. |

| Rock brittleness index | Triaxial tests, Brazilian tests, Mineral Composition Analysis, Sonic Logs | Determines the ease of fracture creation and the complexity of the fracture network. |

| Fracture Toughness | Laboratory Testing (e.g., Chevron-Notched Short Rod) | Governs the resistance of the rock to fracture propagation. |

| Natural Fracture Characteristics | Borehole imaging, Core analysis | Influences fracture network connectivity and fluid flow pathways. |

Case Studies of Geomechanical Applications in EGS

Several successful EGS projects have demonstrated the importance of incorporating geomechanical principles into reservoir development. For example, the Soultz-sous-Forêts project in France utilized extensive in-situ stress measurement and fracture characterization to optimize stimulation strategies and enhance reservoir permeability. The Newberry EGS Demonstration Project in Oregon also highlighted the significance of understanding rock brittleness index in selecting appropriate stimulation fluids and injection rates. These case studies underscore the value of a comprehensive geomechanical approach for achieving successful and sustainable geothermal energy production.

Future Trends in Geomechanics for EGS

The field of geomechanics for EGS is constantly evolving, with new technologies and methodologies emerging to improve our understanding of subsurface conditions and optimize reservoir stimulation strategies. Some key trends include:

- Advanced stress measurement techniques, such as distributed fiber optic sensing (DFOS), which provide continuous stress monitoring along the length of a wellbore.

- Development of more sophisticated geomechanical models that can capture the complex interactions between fluid flow, heat transfer, and rock deformation.

- Integration of machine learning and artificial intelligence to analyze large datasets and identify optimal stimulation parameters.

- Development of novel stimulation fluids and techniques that can enhance fracture complexity and improve reservoir connectivity.

These advancements will play a critical role in unlocking the full potential of Enhanced Geothermal Systems as a reliable and sustainable source of geothermal energy.

| Equation | Description | Relevance to EGS |

|---|---|---|

| Terzaghi's Effective Stress Principle: σ' = σ - αp | Relates effective stress (σ') to total stress (σ), pore pressure (p), and Biot's coefficient (α). | Crucial for understanding fracture aperture changes during stimulation and production. |

| Griffith's Fracture Criterion: σ1 = 3σ3 + √8σt (for compression) | Predicts fracture initiation based on principal stresses (σ1, σ3) and tensile strength (σt). | Informs the design of hydraulic fracturing operations. |

| Stress Intensity Factor (KI): KI = σ√(πa) (for a simple crack) | Quantifies the stress concentration at the tip of a crack. (σ is the applied stress and a is the crack length) | Predicts fracture propagation. |

| Biot-Gassmann Equation (for Bulk Modulus Changes) | Predicts changes in bulk modulus due to fluid saturation. | Necessary for understanding how fluid injection will affect the stress state of the rock. |

FAQ: Geomechanics and Enhanced Geothermal Systems

Here are some frequently asked questions about the role of geomechanics in EGS development:

Q: Why is understanding in-situ stress so important for EGS?

A: In-situ stress controls the orientation and aperture of fractures, which are the pathways for fluid flow in an EGS reservoir. Accurate stress measurements are essential for designing effective stimulation strategies and maximizing the surface area of the stimulated reservoir volume.

Q: How does rock brittleness index affect EGS performance?

A: A high rock brittleness index indicates that the rock is more likely to fracture during stimulation, leading to the creation of a more complex and interconnected fracture network. This enhances permeability and improves heat extraction.

Q: What is the role of fracture mechanics in EGS?

A: Fracture mechanics provides the theoretical framework for predicting how fractures will initiate and propagate during hydraulic fracturing. This knowledge is essential for optimizing stimulation parameters and controlling the geometry of the stimulated reservoir volume.

Q: How can geomechanical data be integrated into reservoir simulation?

A: Geomechanical data can be incorporated into reservoir simulation models by using coupled geomechanical-reservoir simulators. These simulators account for the effects of stress changes on permeability and porosity, providing a more realistic representation of reservoir behavior.

Q: What are some of the challenges in applying geomechanics to EGS?

A: Some of the challenges include the difficulty of accurately measuring in-situ stress at depth, the heterogeneity of subsurface formations, and the complexity of fracture networks. Ongoing research is focused on developing new technologies and methodologies to address these challenges and improve our understanding of geomechanical processes in EGS reservoirs.