EGS Longevity: Mastering Fluid Flow for Sustainable Heat

Introduction to Sustainable Heat Extraction from Enhanced Geothermal Systems

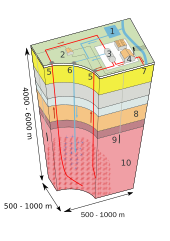

The pressing need for clean and renewable energy sources has propelled the development of innovative technologies, with Geothermal Energy playing a crucial role. Among the various geothermal approaches, Enhanced Geothermal Systems (EGS) offer a promising avenue for tapping into the vast, previously inaccessible heat resources deep beneath the Earth's surface. Unlike conventional geothermal resources that rely on naturally occurring hydrothermal reservoirs, EGS involve creating artificial reservoirs by fracturing hot, dry rocks and circulating fluid to extract heat. This process of Sustainable Heat Extraction hinges significantly on understanding and optimizing Fluid Circulation dynamics and accurately predicting the Thermal Lifespan of these projects. The viability of EGS as a reliable energy source depends not only on the initial Heat Extraction Rate but also on its long-term sustainability, which is directly linked to how effectively we manage the Geothermal Reservoir Simulation and model the Thermo-Hydraulic Modeling aspects of the system. This article delves into the intricate details of fluid circulation, its impact on heat extraction efficiency, and the factors that govern the thermal lifespan of EGS projects, providing a comprehensive overview for researchers, engineers, and anyone interested in this cutting-edge Sustainable Energy technology.

Fluid Circulation Dynamics in EGS Reservoirs

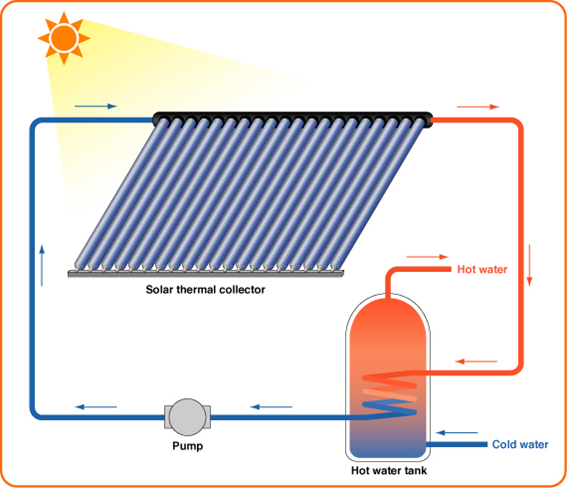

Efficient Fluid Circulation is the lifeblood of any EGS project. The process involves injecting a working fluid, typically water or a brine solution, into the fractured rock formation. This fluid then circulates through the network of fractures, absorbing heat from the surrounding rock before being extracted back to the surface. The effectiveness of this circulation is governed by a complex interplay of factors, including the fracture network geometry, the permeability of the rock mass, the injection and production well configurations, and the thermo-physical properties of the fluid and rock. The pressure gradients established between the injection and production wells drive the fluid flow, and the resistance to flow offered by the fracture network determines the overall circulation rate. Uneven fracture distribution can lead to preferential flow paths, resulting in some areas of the reservoir being swept more efficiently than others, ultimately impacting the overall Heat Extraction Rate and Thermal Lifespan. Optimizing Fluid Circulation is therefore paramount for maximizing energy production and ensuring the economic viability of EGS projects. This requires detailed characterization of the subsurface geology and fracture network, coupled with sophisticated Geothermal Reservoir Simulation techniques to predict fluid flow patterns and temperature distributions.

Factors Influencing Fluid Flow

Several key factors play a crucial role in determining the efficiency of fluid flow within an EGS reservoir. Understanding and managing these factors is essential for optimizing heat extraction and extending the Thermal Lifespan of the project.

Fracture Network Characteristics

The geometry and connectivity of the fracture network dictate the pathways available for fluid flow. A well-connected network with high permeability allows for efficient circulation and heat transfer. The density, orientation, and aperture of fractures all contribute to the overall permeability of the reservoir.

Injection and Production Strategies

The location, number, and flow rates of injection and production wells significantly impact the pressure gradients and flow patterns within the reservoir. Optimizing well configurations can help to ensure uniform sweep of the reservoir and prevent short-circuiting of flow.

Understanding of the Geothermal Reservoir Simulation is paramount to effectively predict and manage Fluid Circulation. These simulations rely heavily on accurate Thermo-Hydraulic Modeling, which takes into account the complex interactions between fluid flow, heat transfer, and rock mechanics. By incorporating detailed geological and geophysical data, as well as laboratory measurements of rock and fluid properties, these models can provide valuable insights into the performance of the EGS reservoir. These insights help to predict the Heat Extraction Rate and optimize operating parameters to maximize energy production and extend the Thermal Lifespan of the project.

Thermal Lifespan of EGS Projects

The Thermal Lifespan of an EGS project refers to the period over which it can sustainably produce heat at an economically viable rate. This lifespan is influenced by several factors, including the initial reservoir temperature, the Heat Extraction Rate, the size and extent of the fractured rock volume, and the efficiency of Fluid Circulation. As heat is extracted from the reservoir, the rock temperature gradually decreases, leading to a decline in the temperature of the produced fluid. Eventually, the temperature may fall below a threshold that makes continued operation uneconomical. Accurately predicting the Thermal Lifespan is crucial for assessing the long-term viability of EGS projects and for making informed decisions about investment and resource management. This prediction requires sophisticated Geothermal Reservoir Simulation that can accurately model the complex heat transfer processes occurring within the reservoir.

In addition to the factors mentioned above, the Thermal Lifespan of an EGS project can also be affected by factors such as thermal stress cracking and mineral precipitation. Thermal stress cracking can enhance permeability and improve Fluid Circulation in the near-well region, leading to a localized increase in Heat Extraction Rate. Conversely, mineral precipitation can reduce permeability and impede fluid flow, potentially accelerating the decline in production.

Strategies for Extending Thermal Lifespan

Various strategies can be employed to extend the Thermal Lifespan of EGS projects and improve their long-term sustainability.

Optimized Reservoir Management

Careful monitoring and management of injection and production rates can help to maintain reservoir pressure and temperature, preventing premature decline in production. Balancing fluid extraction with fluid injection helps to sustain reservoir pressure and maintain a stable Heat Extraction Rate.

Enhanced Fracture Stimulation

Periodic refracturing can help to restore permeability and improve Fluid Circulation in areas where flow has become restricted. This can rejuvenate the reservoir and extend its productive lifespan.

The process of Thermo-Hydraulic Modeling becomes invaluable when trying to accurately determine the expected Thermal Lifespan of an EGS. By understanding the physics and chemistry occurring, more accurate predictions can be made and the project's Sustainable Energy output potential can be better estimated.

Challenges and Future Directions

Despite the significant potential of EGS, several challenges remain to be addressed before it can become a widespread and economically competitive source of Sustainable Energy. Accurately characterizing the subsurface geology and fracture network is crucial for effective reservoir stimulation and management. This often requires expensive and time-consuming geophysical surveys and well testing. Developing robust and reliable Geothermal Reservoir Simulation tools is also essential for predicting reservoir performance and optimizing operating parameters. The high costs associated with drilling, stimulation, and infrastructure development can be a barrier to entry for many projects. Addressing these challenges will require continued research and development in areas such as advanced drilling techniques, fracture characterization methods, and reservoir modeling. Future directions include exploring the use of supercritical fluids as working fluids to enhance Heat Extraction Rate, developing innovative stimulation techniques to create more complex and interconnected fracture networks, and integrating EGS with other renewable energy sources to create hybrid energy systems. The success of these efforts will be crucial for unlocking the full potential of EGS and realizing its contribution to a sustainable energy future.

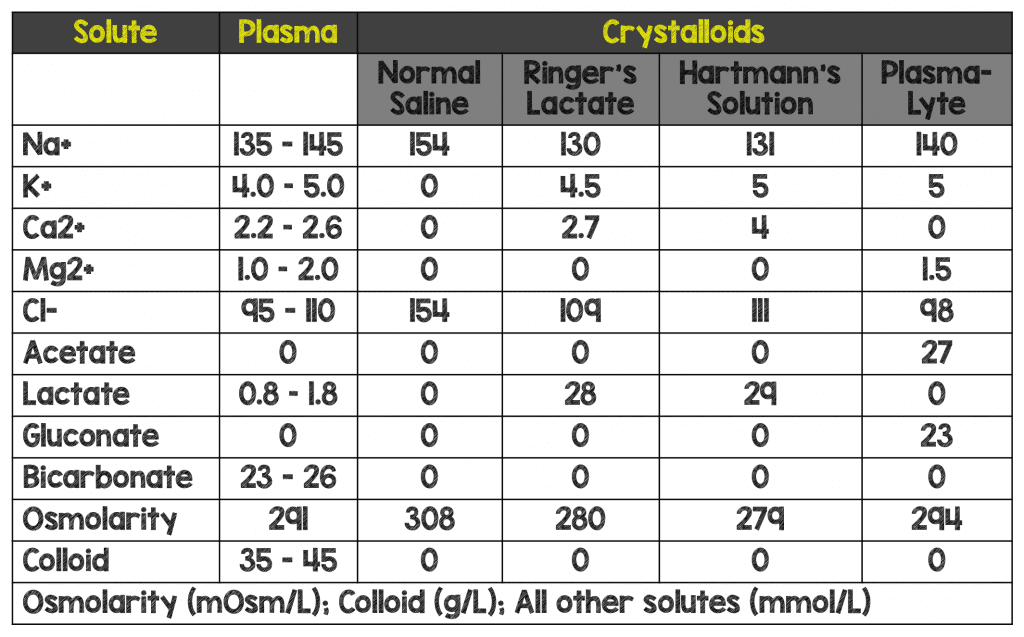

Fluid Properties and their Impact on Heat Extraction

The selection and management of the circulating fluid are critical aspects of EGS projects that significantly influence both the Heat Extraction Rate and the Thermal Lifespan. Water is the most commonly used fluid due to its abundance, low cost, and high heat capacity. However, other fluids, such as CO2 or engineered working fluids, are also being investigated for their potential to enhance heat extraction efficiency. The thermo-physical properties of the fluid, including its density, viscosity, and thermal conductivity, play a crucial role in determining its ability to absorb and transport heat. The chemical composition of the fluid can also affect its performance, as certain dissolved minerals can lead to scaling and corrosion, which can reduce permeability and impede fluid flow.

| Fluid Type | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Water | High heat capacity, low cost, readily available | Potential for scaling and corrosion, limited high-temperature performance | Most EGS projects, especially those with moderate reservoir temperatures |

| CO2 | Higher density and lower viscosity than water, potentially enhanced heat extraction | Corrosive, potential for leakage, requires specialized equipment | EGS projects with high reservoir temperatures and pressures |

| Engineered Working Fluids | Tailored thermo-physical properties, improved heat transfer | High cost, potential environmental concerns, limited availability | Specialized EGS projects requiring high efficiency and performance |

Effective management of the circulating fluid involves monitoring its chemical composition, adjusting its pH, and implementing scale and corrosion inhibitors to maintain optimal performance. Regular analysis of fluid samples can help to identify potential problems early on and prevent costly damage to the reservoir and equipment. Choosing the right fluid and managing it effectively can significantly improve the Heat Extraction Rate and extend the Thermal Lifespan of EGS projects, contributing to their long-term sustainability and economic viability. The principles of Reservoir Engineering are used to determine the optimal conditions for fluid injection and extraction.

Reservoir Engineering Principles in EGS Longevity

The longevity and sustainability of Enhanced Geothermal Systems (EGS) are deeply intertwined with the application of sound Reservoir Engineering principles. These principles govern how we manage the Geothermal Reservoir Simulation, optimize Fluid Circulation, and ultimately, predict and influence the Thermal Lifespan of a project. Effective Reservoir Engineering requires a comprehensive understanding of the reservoir's geological characteristics, including its fracture network, permeability, and thermal properties. By applying these principles, engineers can develop strategies to maximize the Heat Extraction Rate while ensuring the long-term viability of the resource.

| Principle | Description | Impact on Thermal Lifespan |

|---|---|---|

| Pressure Management | Maintaining optimal reservoir pressure through balanced injection and production rates. | Prevents premature decline in production, enhances fluid circulation, and reduces the risk of induced seismicity. |

| Sweep Efficiency Optimization | Maximizing the contact area between the circulating fluid and the hot rock mass. | Ensures efficient heat extraction from the entire reservoir volume, extending the time it takes for the reservoir to cool down. |

| Thermal Breakthrough Management | Delaying the arrival of cooler injected fluid at the production wells. | Maintains high production temperatures and prevents a rapid decline in heat extraction rate. |

| Scale and Corrosion Control | Preventing the formation of mineral deposits and corrosion of equipment due to the interaction between the fluid and the reservoir rock. | Ensures the long-term integrity of the reservoir and equipment, preventing costly downtime and maintaining efficient fluid circulation. |

The successful implementation of these Reservoir Engineering principles relies on continuous monitoring of reservoir performance, using data from well tests, temperature logs, and pressure measurements. This data is then used to refine the Geothermal Reservoir Simulation models and adjust operating parameters as needed. By adopting a proactive and adaptive approach to Reservoir Engineering, operators can significantly enhance the Sustainable Heat Extraction from EGS projects and ensure their long-term economic viability. The process requires an in-depth understanding of the Thermo-Hydraulic Modeling involved.

FAQ: Sustainable Heat Extraction and EGS Lifespan

Below are some frequently asked questions about Sustainable Heat Extraction, Fluid Circulation, and the Thermal Lifespan of EGS projects.

Q: How long can an EGS project realistically produce heat?

A: The Thermal Lifespan of an EGS project can vary significantly, ranging from 20 to 50 years or even longer, depending on factors such as reservoir size, Heat Extraction Rate, and the effectiveness of Reservoir Engineering strategies. With optimized management and potential refracturing, the lifespan can be further extended. The Geothermal Reservoir Simulation models used play a pivotal role in accurately predicting this lifespan.

Q: What are the main factors limiting the thermal lifespan of EGS projects?

A: The primary factors include the gradual cooling of the reservoir rock due to heat extraction, the decline in permeability due to mineral precipitation or thermal stress, and the potential for thermal breakthrough, where cooler injected fluid reaches the production wells. Effective Fluid Circulation management and mitigation strategies are crucial for overcoming these limitations.

Q: Can the environmental impact of EGS projects be minimized?

A: Yes, the environmental impact of EGS projects can be minimized through careful site selection, proper well construction and operation, and the implementation of closed-loop systems that prevent the release of geothermal fluids to the environment. Induced seismicity is a concern that can be mitigated through careful monitoring and pressure management. By continually improving our understanding of Thermo-Hydraulic Modeling, we can mitigate potential negative environmental impacts.