Caprocks: Hydrothermal Lifeline or EGS Achilles Heel?

The Critical Role of Caprocks in Geothermal Systems

The successful harnessing of geothermal energy, whether from naturally occurring hydrothermal systems or engineered enhanced geothermal systems (EGS), hinges significantly on the presence and characteristics of caprocks. These geological formations act as essential barriers, preventing the escape of heated fluids and maintaining the pressure necessary for efficient energy extraction. Understanding the sealing mechanism of caprocks is paramount to predicting reservoir performance and ensuring the long-term viability of geothermal projects. Without adequate caprock integrity, the economic feasibility and environmental sustainability of both natural and engineered systems are severely compromised.

Caprocks in Natural Hydrothermal Systems: Nature's Pressure Cooker

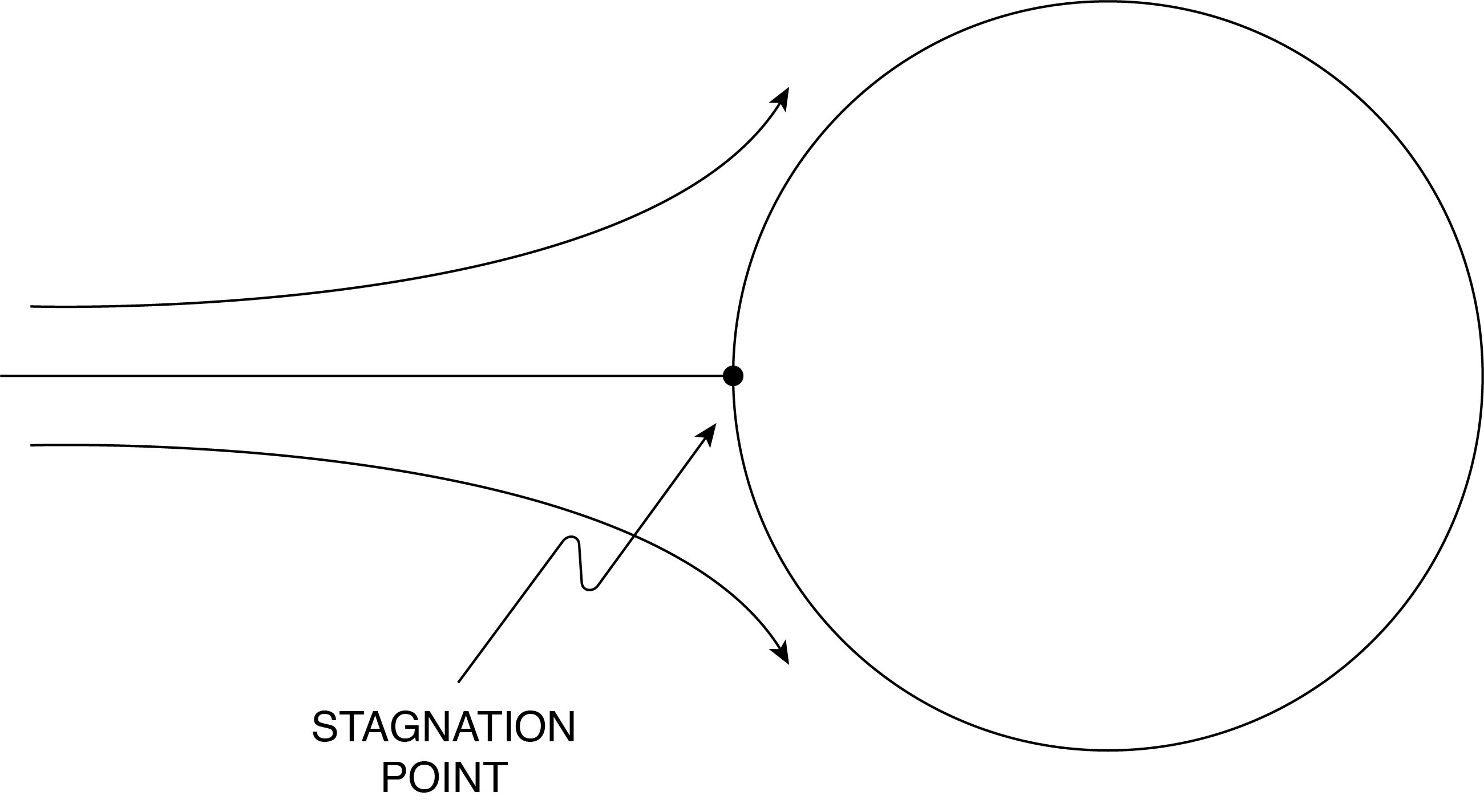

In natural hydrothermal systems, caprocks play a vital role in trapping geothermal fluids. These fluids, heated by the Earth's internal heat, circulate through permeable rocks until they encounter an overlying impermeable layer – the caprock. The sealing mechanism of the caprock prevents the hot, buoyant fluids from escaping to the surface, allowing pressure to build up within the reservoir. This pressure difference between the reservoir and the surrounding environment is what drives fluid flow and allows for the extraction of geothermal energy. The effectiveness of a caprock is determined by its low permeability, its thickness, and its resistance to fracturing under pressure. A compromised caprock can lead to leakage, reduced reservoir pressure, and ultimately, a decline in energy production.

The type of rock that constitutes a caprock significantly influences its sealing mechanism. Clay-rich shales are particularly effective due to their fine grain size and ability to deform plastically, sealing fractures and faults. Evaporite deposits, such as anhydrite and halite, can also act as excellent caprocks due to their very low permeability and self-sealing properties. However, their solubility in water can be a limiting factor in certain environments. Understanding the mineralogical composition and geomechanics of the caprock is crucial for assessing its long-term caprock integrity.

Factors Affecting Caprock Integrity in Natural Systems

Fault Reactivation

Existing faults within or adjacent to the caprock can be reactivated by changes in pore pressure or tectonic stress. This fault sealing process is complex and depends on the fault's orientation, the stress regime, and the presence of sealing materials like clay gouge. Reactivation can compromise the sealing mechanism and lead to fluid leakage.

Chemical Alteration

The interaction between geothermal fluids and the caprock can lead to chemical alteration of the rock matrix. Dissolution of minerals can increase permeability, while precipitation of new minerals can seal fractures. The overall effect on caprock integrity depends on the specific geochemical conditions and the mineralogical composition of the caprock.

Thermal Stress

Repeated heating and cooling cycles can induce thermal stress within the caprock, leading to fracturing and a decrease in caprock integrity. The magnitude of the thermal stress depends on the temperature variations and the thermal properties of the caprock rock.

Caprocks in Enhanced Geothermal Systems (EGS): A Man-Made Reservoir

In contrast to natural hydrothermal systems, enhanced geothermal systems (EGS) involve the creation of artificial reservoirs in hot, dry rocks. This process typically involves hydraulic fracturing to increase permeability and allow for fluid circulation. However, the success of an EGS project also relies heavily on the presence of a suitable caprock to contain the injected fluids and prevent them from escaping into surrounding formations. The caprock in an EGS acts as a crucial component in maintaining reservoir pressure and ensuring efficient heat extraction. The sealing mechanism of the caprock in an EGS is subject to different challenges compared to natural systems, as the caprock integrity can be impacted by the hydraulic fracturing process itself and by the long-term effects of fluid injection.

The selection of a suitable site for an EGS project must consider the existing geological conditions, including the presence of a thick and impermeable caprock. Unlike natural systems where the caprock has formed over geological timescales, the caprock in an EGS must be able to withstand the stresses induced by hydraulic fracturing and the long-term effects of fluid injection. Therefore, a thorough understanding of the geomechanics of the caprock is essential for predicting its response to these induced stresses and ensuring its long-term sealing mechanism.

Challenges to Caprock Integrity in EGS

Fracture Propagation

Hydraulic fracturing can induce fracture propagation in the caprock, creating pathways for fluid leakage. The extent of fracture propagation depends on the injection pressure, the stress state of the caprock, and the presence of pre-existing fractures. Managing injection pressures is critical to controlling fracture propagation and preserving caprock integrity.

Induced Seismicity

Fluid injection can trigger induced seismicity, which can reactivate existing faults in the caprock and compromise its sealing mechanism. Monitoring seismic activity and adjusting injection parameters can help to minimize the risk of induced seismicity.

Geochemical Reactions

The injected fluids can react with the caprock, leading to dissolution or precipitation of minerals. These reactions can alter the permeability and mechanical properties of the caprock, affecting its long-term caprock integrity. Understanding the geochemical compatibility of the injected fluids with the caprock is crucial for mitigating these risks.

Comparative Analysis: Natural Hydrothermal vs. EGS Caprocks

While the fundamental role of caprocks remains the same in both natural hydrothermal systems and enhanced geothermal systems (EGS) – to contain and seal geothermal fluids – the mechanisms and challenges related to their caprock integrity differ significantly. In natural systems, the caprock has evolved over geological timescales, adapting to the prevailing pressure and temperature conditions. Its sealing mechanism is often well-established and relatively stable, although it can be affected by tectonic activity or chemical alteration. In contrast, the caprock in an EGS is subjected to rapid and significant changes in pressure and stress due to hydraulic fracturing and fluid injection. This can lead to fracture propagation, induced seismicity, and geochemical reactions, all of which can compromise its caprock integrity. Therefore, the assessment and management of caprock risks are much more critical in EGS projects than in natural hydrothermal systems.

The following table summarizes the key differences between caprocks in natural hydrothermal systems and EGS:

| Feature | Natural Hydrothermal Systems | Enhanced Geothermal Systems (EGS) |

|---|---|---|

| Formation Time | Geological Timescales | Relatively Short (Project Lifespan) |

| Stress Regime | Relatively Stable | Dynamic, Influenced by Hydraulic Fracturing |

| Fluid Injection | Natural Fluid Circulation | Induced Fluid Injection |

| Primary Risks | Tectonic Activity, Chemical Alteration | Fracture Propagation, Induced Seismicity, Geochemical Reactions |

| Monitoring | Less Intensive | More Intensive, Requires Continuous Monitoring |

Techniques for Assessing and Monitoring Caprock Integrity

Ensuring caprock integrity is crucial for the long-term success of both natural hydrothermal systems and enhanced geothermal systems (EGS). Various techniques are employed to assess and monitor the condition of caprocks, ranging from geological and geophysical surveys to geochemical analyses and microseismic monitoring. These techniques provide valuable insights into the sealing mechanism of the caprock and help to identify potential risks to its caprock integrity.

Geological and geophysical surveys, such as seismic reflection and gravity surveys, can be used to characterize the structure and properties of the caprock. These surveys can help to identify faults, fractures, and other geological features that may affect its sealing mechanism. Geochemical analyses of groundwater samples can provide information about the chemical composition of the fluids and their potential to react with the caprock. Microseismic monitoring can detect small earthquakes induced by fluid injection, providing valuable information about the stress state of the caprock and the potential for fault sealing or reactivation. Integration of these different techniques provides a comprehensive understanding of the caprock integrity and allows for informed decision-making regarding reservoir management.

The following table shows monitoring methods and their specific use cases.

| Monitoring Method | Description | Use Cases |

|---|---|---|

| Microseismic Monitoring | Detects small earthquakes induced by fluid injection. | Detecting fault reactivation, mapping fracture propagation, assessing stress changes. |

| Tracer Testing | Injects tracers into the reservoir and monitors their arrival at production wells. | Identifying flow pathways, assessing reservoir connectivity, detecting fluid leakage. |

| Geochemical Monitoring | Analyzes the chemical composition of groundwater and produced fluids. | Detecting changes in fluid composition, identifying geochemical reactions, assessing scaling potential. |

| Ground Deformation Monitoring (InSAR) | Uses satellite radar interferometry to measure ground deformation. | Detecting subsidence or uplift related to fluid extraction or injection. |

| Pressure Monitoring | Monitors pressure changes in the reservoir and surrounding formations. | Assessing reservoir performance, detecting fluid leakage, managing injection pressures. |

Future Directions and Research Needs

The reliable long-term performance of both natural hydrothermal systems and enhanced geothermal systems (EGS) is directly linked to the effective sealing mechanism of their respective caprocks. Further research is crucial to refine our understanding of caprock integrity, particularly concerning the complex interplay between geomechanics, fluid chemistry, and temperature. Developing advanced monitoring techniques that can provide real-time assessment of caprock conditions is a critical need. This includes exploring the potential of fiber optic sensing, distributed temperature sensing (DTS), and advanced microseismic analysis to detect subtle changes in stress, strain, and fluid flow within the caprock. Moreover, research should focus on developing strategies to mitigate the risks associated with fault sealing failures, induced seismicity, and geochemical alteration, ultimately ensuring the sustainable exploitation of geothermal energy.

FAQ

Q: What happens if a caprock fails?

A: If a caprock fails, the pressurized geothermal fluids within the reservoir can escape, leading to a decrease in reservoir pressure and a reduction in geothermal energy production. In EGS, this can also result in fluid loss and potentially trigger induced seismicity.

Q: What are the best types of rocks for caprocks?

A: Ideally, effective caprocks are made of rocks with very low permeability and good mechanical strength. Examples include shales, claystones, and evaporite deposits like anhydrite and halite. The specific suitability depends on the local geological conditions and fluid chemistry.

Q: How can caprock integrity be improved in EGS?

A: Caprock integrity in EGS can be improved through careful site selection, managing injection pressures to minimize fracture propagation, implementing strategies to reduce induced seismicity (e.g., traffic light systems), and using fluids that are geochemically compatible with the caprock.