The Ultimate Guide to Silicosis Prevention for Earth Scientists: Protecting Your Health in the Field

Imagine standing at the edge of a vast quarry, the sun beating down, dust swirling around you as heavy machinery grinds away at the earth. Each breath carries microscopic particles of rock, a silent threat to your long-term health. This isn't just a scene from a documentary; it's the reality for many earth scientists. The potential for silica dust exposure is ever-present, making a thorough understanding of prevention strategies not just recommended, but absolutely essential.

Understanding Silicosis and its Risks

Silicosis is a debilitating and irreversible lung disease caused by the inhalation of crystalline silica dust. This dust, commonly found in materials like quartz, granite, and sandstone, is a constant companion in many earth science activities. When inhaled, these tiny particles lodge deep within the lungs, causing inflammation and scarring that progressively impairs breathing. The severity of silicosis can range from chronic (developing after 10 or more years of exposure) to accelerated (developing within 5-10 years) to acute (developing within weeks or months of very high exposure). Unfortunately, there is no cure for silicosis; treatment focuses on managing symptoms and preventing further lung damage. According to a 2023 report by the National Institute for Occupational Safety and Health (NIOSH), approximately 2.3 million U.S. workers are exposed to respirable crystalline silica in their workplaces, highlighting the widespread nature of this hazard.

Understanding the specific activities that pose the greatest risk is crucial. These activities often include:

- Drilling and coring rock samples

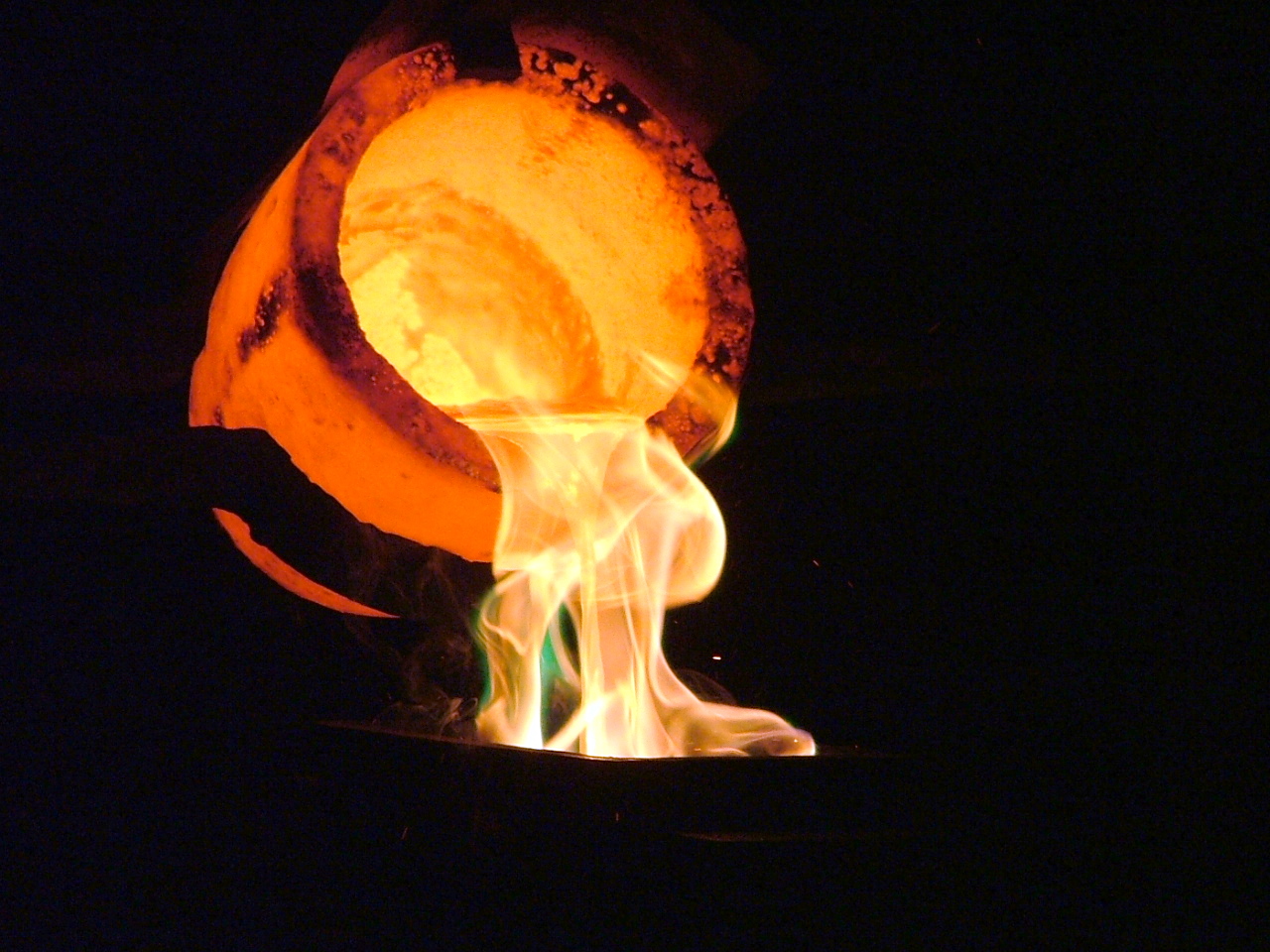

- Crushing and grinding rocks and minerals

- Excavation and trenching

- Sandblasting or abrasive blasting (especially using silica sand)

- Working with concrete and masonry materials

Each of these activities generates respirable silica dust, putting you at risk if preventative measures are not properly implemented.

Conducting a Thorough Silicosis Risk Assessment

A comprehensive silicosis risk assessment is the cornerstone of any effective prevention program. This process involves identifying potential sources of silica dust exposure, evaluating the level of risk associated with each source, and implementing appropriate control measures. A poorly executed risk assessment can leave critical vulnerabilities unaddressed, putting workers at unnecessary risk. The assessment should be documented and regularly reviewed, especially when processes or materials change.

Identifying Silica Exposure Sources

The first step is to meticulously identify all potential sources of respirable crystalline silica dust within the work environment. This includes pinpointing specific tasks, equipment, and materials that could release silica. For example, are drills equipped with dust collection systems? Are workers cutting concrete without water suppression? Document these observations carefully.

Evaluating the Level of Risk

Once you've identified potential sources, assess the level of risk associated with each. This involves considering factors such as the frequency and duration of exposure, the concentration of silica dust in the air, and the effectiveness of existing control measures. Use available data, such as air monitoring results, to quantify exposure levels. Qualitative assessments, based on visual observations and worker interviews, can also provide valuable insights. Prioritize the highest-risk activities for immediate attention.

Prioritizing Risk Mitigation

Based on the risk assessment, prioritize the implementation of control measures. Focus on the highest-risk activities first. Ensure that all control measures are properly implemented, maintained, and regularly inspected. Communicate the risks and control measures to all affected workers through comprehensive training and hazard communication programs.

Implementing Engineering Controls for Dust Suppression

Engineering controls are the most effective way to minimize silica dust exposure. These controls physically remove or isolate the hazard, preventing it from reaching workers. Prioritizing engineering controls over other measures like personal protective equipment (PPE) is always the best practice, as they offer a more reliable and sustainable solution. The hierarchy of controls prioritizes elimination and substitution followed by engineering controls, administrative controls and lastly PPE.

Examples of effective engineering controls include:

- Water Suppression: Using water sprays or misters to wet down materials and suppress dust generation during cutting, drilling, and grinding.

- Local Exhaust Ventilation: Capturing dust at its source using ventilation systems equipped with HEPA filters. This is particularly effective for stationary equipment like crushers and grinders.

- Enclosure: Enclosing dusty processes to isolate them from the rest of the work area. This can be achieved with physical barriers or through the use of enclosed equipment.

- Substitution: Replacing materials containing crystalline silica with less hazardous alternatives. For example, using non-silica abrasives in sandblasting operations.

It's critical to ensure that these engineering controls are properly maintained and operated. Regular inspections and maintenance can prevent malfunctions and ensure their continued effectiveness. According to the OSHA, implementing effective dust suppression techniques can drastically reduce silica dust exposure by up to 90%.

Utilizing Personal Protective Equipment (PPE) Effectively

While engineering controls are the primary line of defense, personal protective equipment (PPE) plays a crucial role in providing additional protection when silica dust exposure cannot be completely eliminated. However, PPE should always be considered a supplementary measure, not a replacement for effective engineering controls. The selection, fit, and proper use of PPE are critical to its effectiveness.

Essential PPE for silica dust exposure includes:

- Respirators: NIOSH-approved respirators are essential for protecting against inhalation of silica dust. The type of respirator required depends on the level of exposure. Options range from disposable N95 respirators to more advanced powered air-purifying respirators (PAPRs). It's vital to conduct fit testing to ensure a proper seal and that the respirator is appropriate for the task.

- Protective Clothing: Coveralls or other protective clothing can prevent silica dust from contaminating personal clothing and being carried home.

- Eye Protection: Safety glasses or goggles are necessary to protect the eyes from silica dust.

Proper training on the use, maintenance, and limitations of PPE is essential. Workers must understand how to don and doff PPE correctly, how to inspect it for damage, and how to clean and store it properly. Regular fit testing for respirators is also required to ensure they continue to provide adequate protection.

Air Monitoring and Exposure Assessment

Regular air monitoring is essential for quantifying silica dust exposure levels and verifying the effectiveness of control measures. Air monitoring involves collecting and analyzing air samples to determine the concentration of respirable crystalline silica dust in the work environment. This data provides valuable insights into the effectiveness of control measures and helps identify areas where improvements are needed. The results should be promptly communicated to workers, fostering a culture of transparency and trust.

The frequency of air monitoring should be based on the level of risk and the effectiveness of existing control measures. High-risk activities or areas with known high concentrations of silica dust may require more frequent monitoring. It's also important to conduct air monitoring whenever there are changes in processes, materials, or control measures.

Implementing a Robust Hazard Communication Program

A comprehensive hazard communication program is crucial for ensuring that workers are fully informed about the risks of silica dust exposure and the measures they can take to protect themselves. This program should include:

- Training: Providing regular training on the hazards of silica, the signs and symptoms of silicosis, and the proper use of control measures and PPE.

- Labeling: Properly labeling containers of materials containing crystalline silica with clear warnings about the potential hazards.

- Safety Data Sheets (SDS): Making SDSs readily available to workers, providing detailed information about the composition, hazards, and safe handling procedures for materials containing crystalline silica.

The training should be interactive and engaging, using real-world examples and case studies to illustrate the risks of silica dust exposure. Workers should be encouraged to ask questions and provide feedback on the effectiveness of the training. Regular refresher training is also essential to reinforce key concepts and ensure that workers stay up-to-date on the latest safety practices. According to OSHA regulations, employers must provide comprehensive training to employees exposed to crystalline silica at or above the action level of 25 μg/m3 as an 8-hour time-weighted average.

Medical Surveillance Programs

Regular medical surveillance is essential for detecting early signs of silicosis and other respiratory illnesses related to silica dust exposure. These programs typically include:

- Baseline Medical Exam: A comprehensive medical exam before starting work in a silica-exposed environment, including a medical history, physical examination, chest X-ray, and pulmonary function tests.

- Periodic Medical Exams: Regular medical exams, typically every one to three years, to monitor lung health and detect any changes that may indicate silicosis.

- Exit Medical Exam: A final medical exam upon termination of employment or transfer to a non-silica-exposed environment.

The medical surveillance program should be conducted by qualified healthcare professionals who are familiar with the risks of silica dust exposure and the signs and symptoms of silicosis. All medical records should be kept confidential and accessible to workers. It's also crucial to provide workers with information about the results of their medical exams and to offer counseling and support if any health problems are identified.

Enforcement and Compliance with Regulations

Staying informed about and complying with relevant regulations is paramount. Organizations like OSHA (Occupational Safety and Health Administration) set standards for permissible exposure limits (PELs) for respirable crystalline silica dust and outline requirements for engineering controls, PPE, air monitoring, and medical surveillance. Regularly review and update your safety protocols to align with current regulations. Failure to comply with these regulations can result in hefty fines and legal liabilities. Furthermore, and more importantly, non-compliance puts your team at significant risk.

Troubleshooting and Common Challenges

Despite best efforts, challenges may arise in implementing effective silicosis prevention measures. Here's how to address some common issues:

- Dust Control System Failures: Regularly inspect and maintain dust suppression techniques. Have backup systems in place to minimize downtime.

- Respirator Fit Issues: Conduct regular fit tests and provide a variety of respirator sizes and styles to accommodate different facial shapes.

- Worker Resistance to PPE: Address concerns about comfort and usability. Provide training on the importance of PPE and involve workers in the selection process.

- Limited Resources: Prioritize the highest-risk activities and implement cost-effective control measures. Seek assistance from industry associations or government agencies.

Pro Tips for Enhanced Silicosis Prevention

Beyond the basics, consider these proactive strategies:

- Invest in Advanced Technology: Explore innovative dust suppression techniques such as automated misting systems or robotic drilling equipment.

- Promote a Safety Culture: Encourage open communication, report potential hazards, and actively participate in safety initiatives.

- Benchmark Best Practices: Learn from other organizations with successful silicosis prevention programs. Share knowledge and collaborate to improve industry-wide safety standards.

- Regularly Review and Update: Continuously evaluate your program and make adjustments based on new information, changing regulations, and evolving technology.

FAQ: Addressing Common Questions About Silicosis Prevention

| Question | Answer |

|---|---|

| What is the permissible exposure limit (PEL) for respirable crystalline silica? | The OSHA PEL for respirable crystalline silica is 50 micrograms per cubic meter (µg/m3) as an 8-hour time-weighted average. |

| How often should air monitoring be conducted? | Air monitoring frequency depends on the level of risk and the effectiveness of control measures. High-risk activities may require more frequent monitoring. Consult OSHA guidelines for specific requirements. |

| What type of respirator is required for different levels of silica dust exposure? | The type of respirator required depends on the exposure level. Consult a qualified occupational hygienist or safety professional to determine the appropriate respirator for your specific situation. |

| Can silicosis be cured? | Unfortunately, there is no cure for silicosis. Treatment focuses on managing symptoms and preventing further lung damage. |

| What are the early symptoms of silicosis? | Early symptoms of silicosis may include shortness of breath, cough, and fatigue. If you experience any of these symptoms, seek medical attention immediately. |

| How can I tell if my respirator fits properly? | Respirators require a fit test to ensure a proper seal. Fit tests should be conducted annually or whenever there are changes in facial features. |

| Are there materials other than sand that can be used for sandblasting? | Yes, alternative abrasive materials like garnet, steel shot, and aluminum oxide can be used for sandblasting to reduce silica dust exposure. |

Preventing silicosis in the field demands vigilance, knowledge, and a proactive approach. By understanding the risks, implementing effective control measures, and fostering a strong safety culture, we can protect the respiratory health of earth science professionals and ensure a healthier future for all. Remember, your commitment to safety today protects your well-being for years to come. Share your questions, experiences, and best practices in the comments below to help us all learn and improve!