Silicosis Prevention: Geology, Silica Dust & Respiratory Health

Are you a geologist or field worker concerned about the long-term effects of dust exposure on your lung health? Are you unsure about the risks of silica dust exposure and how to properly protect yourself? This guide provides a comprehensive overview of silicosis, focusing on prevention and safety measures tailored for those working in geological fields.

Understanding Silicosis: A Geologist's Perspective

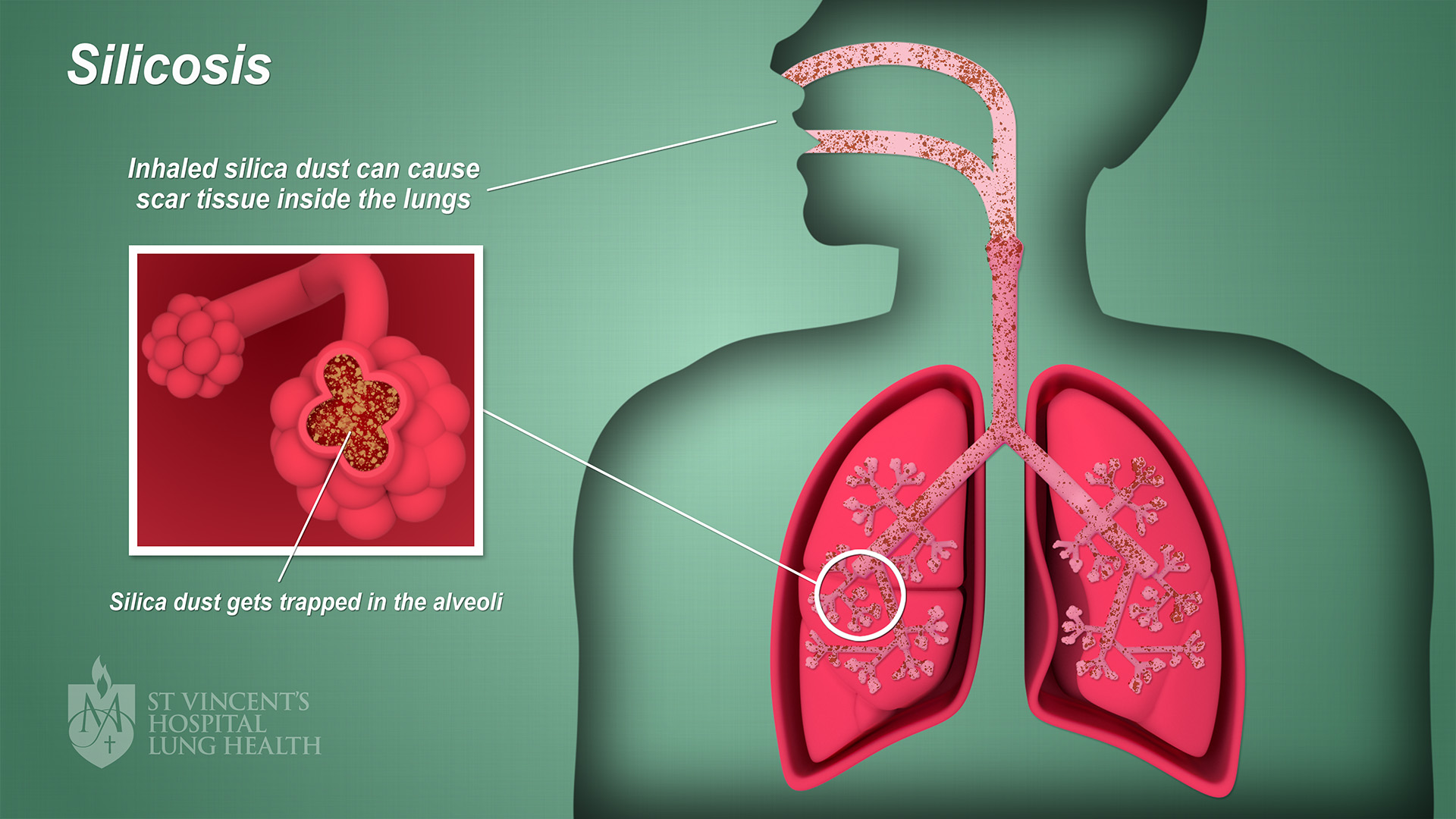

Silicosis is a debilitating and irreversible respiratory disease caused by the inhalation of crystalline silica dust. This dust, generated from activities such as drilling, crushing rocks, and quarrying, poses a significant geological hazard to those working in these environments. It’s crucial to understand the mechanism of the disease to appreciate the importance of silicosis prevention.

When inhaled, fine particles of crystalline silica lodge deep within the lungs, causing inflammation and scarring. Over time, this leads to a reduced ability to breathe and an increased susceptibility to other lung health complications, including tuberculosis and lung cancer. According to a 2024 report by the National Institute for Occupational Safety and Health (NIOSH), approximately 2.3 million workers in the United States are potentially exposed to respirable crystalline silica dust in their workplaces. Geologists and field workers are disproportionately represented in this group due to the nature of their work.

Assessing the Risks in Geological Field Work

Field work safety is paramount, and assessing the risks associated with silica dust exposure is the first crucial step. Consider these factors:

- Type of Rock: Rocks like sandstone, granite, and shale have high silica content.

- Work Activities: Drilling, hammering, sawing, and crushing rocks generate the most dust.

- Environmental Conditions: Dry and windy conditions exacerbate dust dispersion.

- Duration of Exposure: The longer the exposure, the greater the risk.

A thorough risk assessment should involve a detailed examination of the geological environment, the planned activities, and the potential for silica dust generation. Don't underestimate the dangers of even seemingly small amounts of dust inhaled over extended periods.

Implementing Effective Dust Control Measures

Dust control measures are the cornerstone of silicosis prevention. A multi-faceted approach is essential, combining engineering controls, work practices, and personal protective equipment (PPE).

Engineering Controls

Engineering controls are the most effective way to minimize silica dust exposure. These involve modifying the work environment to reduce dust generation or exposure.

- Water Suppression: Using water sprays during drilling, cutting, and grinding operations is highly effective in suppressing dust.

- Ventilation Systems: Local exhaust ventilation systems can capture dust at its source.

- Enclosed Cabs: Utilizing enclosed cabs with filtered air systems in heavy machinery.

Work Practices

Implementing safe work practices can significantly reduce the risk of silica dust exposure.

- Wet Methods: Always use wet methods when cutting or grinding rocks.

- Proper Housekeeping: Regularly clean work areas to remove accumulated dust using wet methods or a vacuum with a HEPA filter. Avoid dry sweeping.

- Restricting Access: Limit access to dusty areas.

Personal Protective Equipment (PPE)

Even with engineering controls and safe work practices, personal protective equipment (PPE) is crucial for minimizing residual risk. Proper selection, fit, and use are essential.

| PPE Item | Description | Important Considerations |

|---|---|---|

| Respirator | A properly fitted N95, P100, or powered air-purifying respirator (PAPR) is essential. | Ensure proper fit testing and regular maintenance. Cartridges must be changed regularly according to the manufacturer's instructions. |

| Eye Protection | Safety glasses or goggles protect the eyes from dust particles. | Choose eyewear that provides a secure fit and adequate peripheral vision. |

| Protective Clothing | Coveralls or other protective clothing prevent dust from settling on skin and clothing. | Wash work clothes separately from personal clothing. |

Developing a Comprehensive Safety Program for Silicosis Prevention

A comprehensive safety program should include the following components:

- Risk Assessment: Conduct a thorough risk assessment of all tasks that may generate silica dust.

- Exposure Monitoring: Regularly monitor silica dust levels in the workplace to assess the effectiveness of control measures.

- Training: Provide comprehensive training to all workers on the hazards of silica dust exposure, proper use of PPE, and safe work practices.

- Medical Surveillance: Offer regular medical examinations, including chest X-rays and pulmonary function tests, to detect early signs of silicosis.

- Record Keeping: Maintain accurate records of exposure monitoring, training, and medical surveillance.

It’s essential to involve all stakeholders, including management, workers, and safety professionals, in the development and implementation of the safety program.

Recognizing the Symptoms and Seeking Medical Attention

Early detection of silicosis is crucial for managing the disease and preventing further lung damage. Be aware of the following symptoms:

- Persistent cough

- Shortness of breath, especially with exertion

- Fatigue

- Chest pain

If you experience any of these symptoms, consult a healthcare professional immediately. Early diagnosis and treatment can help slow the progression of the disease and improve quality of life.

Troubleshooting

- Dust control measures are not effective enough: Review the risk assessment to identify potential gaps. Increase water suppression, improve ventilation, or upgrade PPE.

- Respirator is uncomfortable or doesn't fit properly: Ensure proper fit testing is conducted and provide a variety of respirator models to accommodate different facial shapes.

- Workers are not following safe work practices: Reinforce training and address any barriers to compliance.

FAQ

- What is the permissible exposure limit (PEL) for crystalline silica? The OSHA PEL for respirable crystalline silica is 50 micrograms per cubic meter of air (50 μg/m3) as an 8-hour time-weighted average.

- Can silicosis be cured? Unfortunately, there is no cure for silicosis. However, treatment can help manage the symptoms and slow the progression of the disease.

- How often should I get a medical examination if I am exposed to silica dust? It is recommended to undergo a medical examination, including a chest X-ray and pulmonary function test, every one to three years, depending on the level of exposure.

- Are there resources available to help me implement a silica safety program? Yes, OSHA, NIOSH, and various professional organizations offer resources, training materials, and technical assistance.

Protecting yourself from silicosis requires a proactive and comprehensive approach. By understanding the risks, implementing effective dust control measures, and prioritizing occupational safety, geologists and field workers can significantly reduce their risk of developing this preventable disease. Stay informed, stay vigilant, and prioritize your lung health. If you have any further questions or experiences to share, please leave a comment below – your insights could help protect others in our community.